Manufacturing Process that Set Us Apart

We can provide products that conform to most market specifications, including a wide range of catalog items. Our quality assurance program further complements our ability to deliver products on time with exceptional PPM performance.

Machines and Equipment

Our facility is equipped with computerized and automated workstations, which allows us to guarantee our customers the highest quality in custom magnetic products.

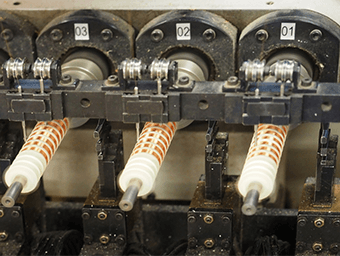

Automated winding machines

We have a variety of multi-spindle CNC winding machines, which are suitable for the manufacture of several different styles of coils. The machines allow excellent control of the winding processes, including termination, as well as being efficient.

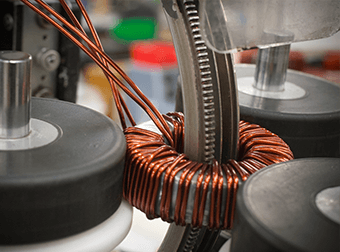

Toroidal coil winding machines

There is a dedicated area for the manufacture of toroidal coils. The methods of manufacture vary from CNC-controlled automated machines to hand winding via an assisted hand-winding method, known as “pull winding.”

Lead-free Soldering Equipment

Numerous lead-free solder pots in a dedicated room have a specific extraction facility.

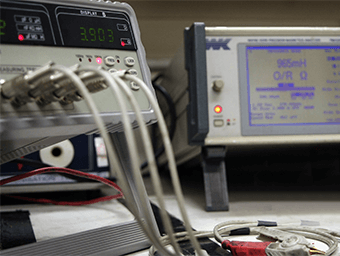

Testing Equipment

Automatic test equipment is used to confirm product conformance in addition to being able to test for all the recognized industry standards parameters.

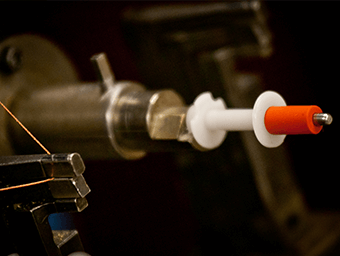

State of the Art Winding

Precision winding enabling 100% standard and requirements conformity

- Benchtop winding machines for high-precision linear winding applications

- CNC-controlled traverse for precise control of tension for guaranteed repeatability

- Pitch accuracy of 0.00004”

- Electronically stored winding programs

- Perfect-layer coils, self-supported coils and edge-wound coils

Encapsulation (Varnish, Casting & Molding) Processes

Satisfying demanding environmental and electrical requirements

- Vacuum & pressure impregnation for HV applications

- Chambers up to 243 inches

- Levels to 100 mTorr

- Fully automated chambers with controls to ensure precision

- Unlimited applications, including flyback transformers, step-gap transformers and inductor

- A diverse variety of sealants, including Anti-fungal & non-nutrient materials

- Custom molds or cups

- Silicones and one or two-part epoxies

Automated Production Testing Equipment

State-of-the-art transformer testers provide a fast, reliable and flexible test solution.

- Continuity

- Magnetic/Exciting Current

- Winding Inductance

- Leakage Inductance

- Winding Resistance

- Open Circuit Voltage

- Loaded Circuit Voltage

- Turns Ratio

- Dielectric Testing (HiPot/High Potential Difference)

- Quality Factor

- Interwinding Capacitance

- Insulation Resistance

Skills & Departments

Our technical staff of engineers can provide you with fast prototyping and product development services for all your magnetic and voltage control needs.

Experienced/skilled workforce

We have an experienced workforce with the manual skills to carry out the hand-winding of intricate coils. This allows the supply of unusual and complicated products unsuitable for machine manufacture.

Multiple Winding Styles

We wound using many different styles including, Bobbin Winding, Toroid Winding, Stick Winding, Unit Winding and Heavy Winding including rectangular wire and Foil to 22.”

Design and Development department

This area supports the customer in product design, prototype manufacture and production engineering. We offer technical and practical support, as well as being able to supply customers with a rapid sampling service.

We aim to use our experience and skill to combine excellent engineering integrity with commercial considerations. This is to provide a product that suits the manufacturer and meets the application’s requirements. Using our extensive winding experience, we ensure the coils are constructed correctly. This means good layering, controlled tension and solid connections.

Product Application

At Shreejee Electronics, our high-performance magnetic components set new standards in various industrial and commercial applications.

Power Management

We manufacture many products that multinational companies use in their power management systems. These systems include converting generated power, controlling outputs and providing supply voltage protection to Ferrite Transformers, Inductors & Chokes.

Sensing Coils

Coils are manufactured to be used in many sensing applications. These applications include sensing movement, object presence and magnetic switching. We also manufacture current sensing coils known as “Rogowski Coils.”

Transformers That Perform

State-of-the-art materials, expert design capability and 100% in-house world-class manufacturing