Autotransformers are a special type of power transformers that feature a single winding wound onto a laminated core. They are used to either step up or step down the voltage. They’re similar to two-winding transformers. However, their differences lie in how the primary and secondary winding are interrelated.

Types of autotransformer

Autotransformers are broadly categorized into two types:

- In the first type, the autotransformer is constructed on a continuous winding model, and taps are introduced at required points based on the desired secondary voltage.

- In the other construction style of an autotransformer, two or more distinct coils are electrically connected to form a continuous winding.

Difference between single-phase transformer and autotransformer

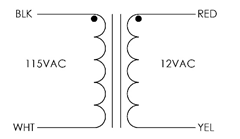

One of the key differences between an autotransformer and a single-phase transformer is the absence of electrically isolated windings. A single-phase transformer comprises the ‘primary’ (supply-side) and ‘secondary’ (load side) winding that share a common magnetic field. Unlike single-phase transformers, an autotransformer’s primary and secondary sides are not electrically isolated from each other; they are continuous.

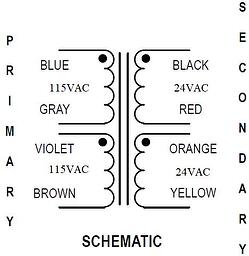

Engineers can convert a single-phase transformer or n-number of phases into an autotransformer by connecting the windings in a series or parallel combination which can be achieved by combining the primary with the secondary to create a step-up or step-down transformer.

In the figure above, each winding has its pair of leads specified using different lead colors. The leads present on the left show the primary windings, while the leads on the right represent the secondary windings of the single-phase transformer. By connecting the primary and secondary windings in series, the transformer would be considered as an autotransformer.

Each series connection will accumulate the voltage for each winding. Wiring the 2 windings in series will sum up the voltages as follows: 115 + 115 + 24 + 24 = 278VAC.

Industry-specific applications of autotransformers

Autotransformers are helpful in applications that require a slight variation of output voltage from the input voltage.

- Autotransformers are used in power applications such as interconnecting systems that operate on different voltage classes, including 132 kV to 66 kV for power transmission.

- In long power distribution lines, autotransformers are fitted with automatic tap-changing equipment injected as voltage regulators to compensate for the loss of voltages during transmission. These specially constructed autotransformers provide the same average voltage at the end of the line.

- Specially manufactured tapped autotransformers are very useful in audio applications that help adapt speakers to constant-voltage audio distribution systems and impedance matching.

- Autotransformers are also used in railway electricity applications. Autotransformer helps in increasing usable transmission distance and reduce the induced interference into any external equipment.

- An autotransformer comes in handy in regulating the voltage and ensures replaced components of an electronic device do not burn. Parts may burn out if unregulated high voltage is supplied to a repaired electronic device. With an autotransformer to slowly power up the repaired device, such damages can be avoided. At the time of powering up an old amplifier or radio, the electrolytic capacitors are reconditioned by applying a reduced voltage through an autotransformer.

- An autotransformer can easily adjust the AC power supply’s output voltage. The speed of a motor is controlled by altering the AC voltage of AC motors that drive fans.

- Users can construct an unregulated DC power supply of a high current with the help of an autotransformer. However, this should only be built if the user is fully aware of the safety concerns associated with an autotransformer. Autotransformers are connected with AC power, making AC voltage directly accessible, thus increasing the risk of electric shock.

Power autotransformer

Autoransformers for Variacs

Advantages of autotransformers

Autotransformers present several advantages over two winding transformers, such as

- Lower cost of production and operation by saving on copper

- Lower losses than standard conventional transformers of the same rating.

When compared to a two-winding transformer, autotransformers also save on copper. Utilized copper wire’s weight for a transformer is proportional to the conductor’s length and area of a cross-section. And this conductor length is proportional to the number of turns. This reduced the no. of winding required, thus saving on costly copper wire.

Disadvantages of Autotransformers

Despite these benefits, autotransformers also have negative aspects, including:

- If an autotransformer converts high voltage to low voltage, the entire primary voltage may come across the terminal in the event of a breakage in the secondary winding.

- A breakage in secondary winding may short the circuit and pose a safety risk to operators’ life and equipment.

Safety Considerations

The primary safety concern when building an autotransformer from an isolation transformer is isolation failure. The isolation is lost when making direct connections by combining windings, either series or parallel. The transformer’s output would then be referenced to the ground, thus making contact with the connection harmful or even fatal.

Some other important considerations while constructing an autotransformer from an isolation transformer with multiple windings are:

- It is crucial to consider the current rating of the windings.

- One must be mindful of the current ratings for each winding to ensure that the transformer does not heat up excessively or, in some extreme cases, melt the magnet wire insulation, causing a short.

- The lowest rated current winding should limit the current rating for the autotransformer.

Autotransformer power transformers from Shreejee Electronics

Shreejee Electronics manufacturers autotransformers in 2 winding models:

- With step-up models, the primary coil will be a percentage of the full winding.

- In step-down models, the secondary coil will be a percentage of the full winding.

The inherent design of the transformer manufactured by Shreejee Electronics enables circuits to be isolated from all power and lighting circuits, thereby allowing a flawless use of grounded or ungrounded circuits. These circuits are independent of the power or lighting grounds.

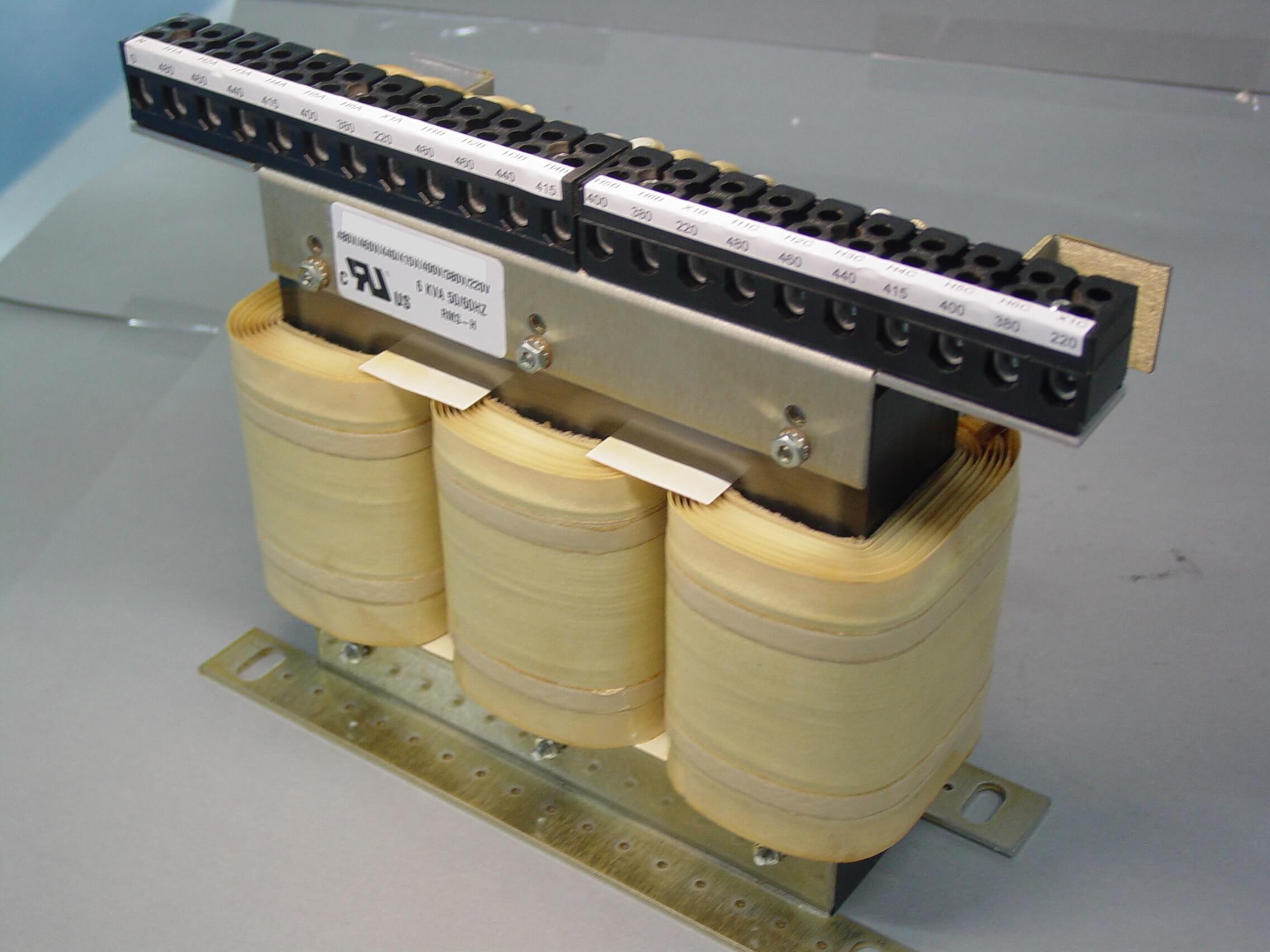

As one of the most reliable suppliers of autotransformers in India, solutions from Shreejee Electronics are exclusively designed to provide the highest level of safety by regulating voltages to machine tool control devices. Our catalog includes three-phase autotransformers that are incredibly efficient when used in applications that call for step-up or step-down voltage but do not require electrical isolation. Our three-phase transformers are compact in size and weight, manufactured using fewer raw materials, and are therefore available at lower costs.

Request a quote today to see how Shreejee Electronics can help you design and manufacture power autotransformers for your applications.