One of the biggest challenges any livestock owner or farmer faces is selecting the proper fencing and equipment for their operation’s needs. Electric fencing should not only keep animals in or out and establish farm boundaries; it should also keep predators and unwanted visitors out.

This article will put out some important buying aspects of the fence energizer

What is Jhatka Machine?

The term jhatka or zatka in Hindi means an electric shock. As soon as an animal walks into the electric fence, it receives a powerful shock created by this zatka machine on the fencing, so it will not continue.

It is also known as a fence energizer.

Types of Jhatka Machine

There are three types of jhatka machines:

- battery-powered,

- solar-powered and

- direct-mains-powered machines.

Battery or solar-powered machines are mainly suitable for portable or temporary fencing systems because they are easy to move. Farmers can also use solar zatka machine in places where there is no power supply. A solar-powered machine charges itself while the user must replace the battery of a battery-powered machine at regular intervals.

It is important to note that a direct mains-powered machine has more power than a battery or a solar-powered jhatka device.

Components of Jhatka Machine

It is broadly composed of six main components:

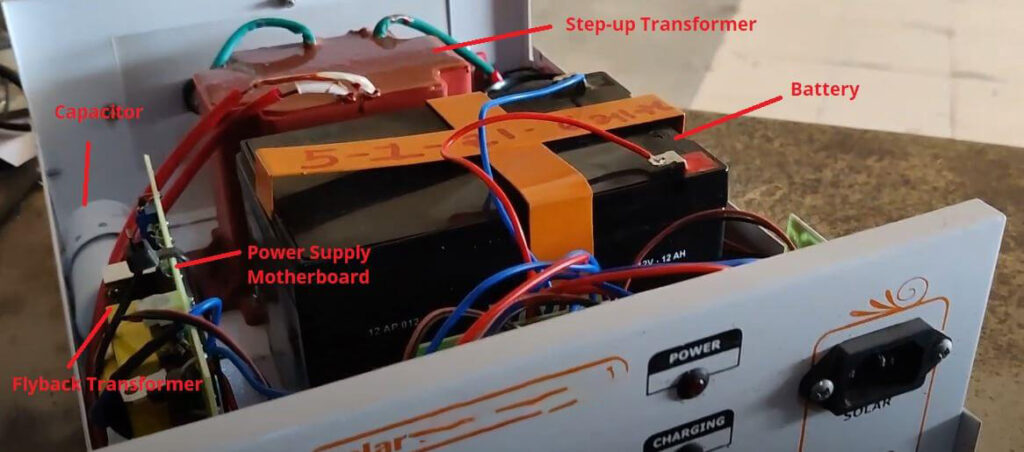

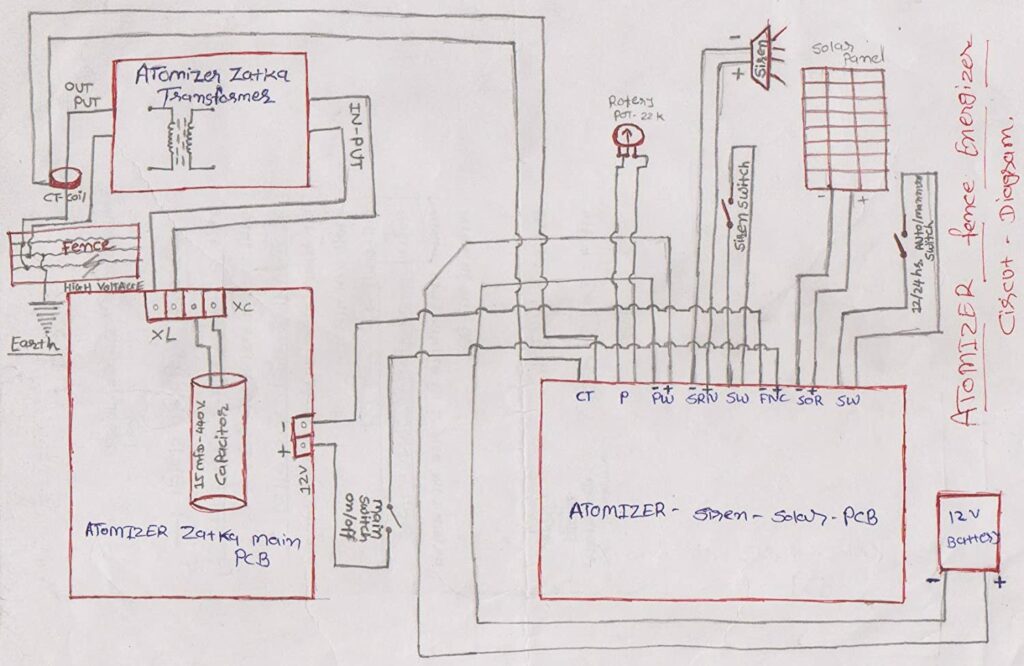

- The power supply is initially fed into a flyback converter (transformer), which transforms the low 220/12 or 9-volt input voltage to about 600 volts and converts the 220-volt Alternating current to Direct Current.

- Converted DC is then fed into the capacitor, which then stores the energy until required. This energy stored into a capacitor is the “Stored Energy” that manufacturers often quote.

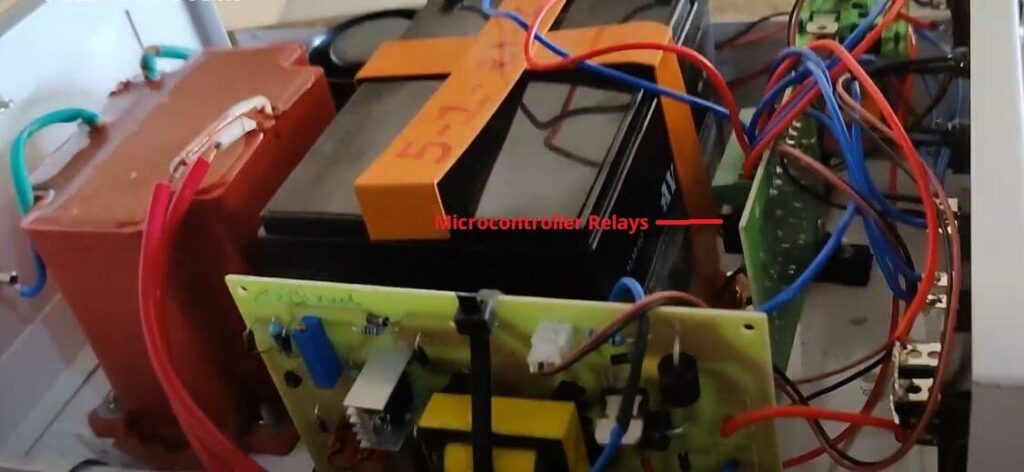

- In the motherboard PCB, an electronic switch or relays controls the intervals at which the stored energy is released. Usually is once per second but may vary between models and manufacturers of the zatka machine.

- The energy is then fed using a microcontroller which monitors and sets the interval – generally in the region of 1/300th of a second.

- This energy flow is then passed through a step-up (iron core) transformer, which converts the 600 volts to very high voltage (6000 – 12000v) depending on the model of the machine. This step-up transformer is the main transformer of the entire kit.

- High voltage in the ranges of 6kV to 12kV is then fed to the fence through the connections. This “Output Energy,” quoted as “Joules,” is the energy available for you to use. This more accurate reflection is always lower than the Stored Energy.

An engineer can design and manufacture a complete zatka machine kit for use using these six main components.

Prices of Jhatka Machine

Prices of such machines depend upon various factors such as:

- Voltage Required: The most critical element of an electric fence is maintaining an adequate voltage charge.

- Flexibility: Portable machines are cheap and cost-effective options than permanently installed energizers.

- Quality: Machines that use high-quality components such as transformers made using premium wires have the least electrical loss are costly than those made using cheap unskilled labor and low-grade scrap materials. Low-quality manufacturers are unable to provide a warranty for the complete machine.

On average, a jhatka machine price ranges from ₹5000 to ₹7500.

Transformers used in Jhatka Machines

Essentially, the kit has two types of transformers in it:

- Flyback transformer for the power supply to convert 220V AC to 600V DC and stored inside capacitor.

- Step-up transformer, made using CRGO or CRNO iron cores to convert stored charge into very high voltages of 6kV to 12kV.

At Shreejee Electronics, our experienced team uses the latest advances in magnetics manufacturing technology to deliver zatka machine transformers that exceed performance expectations.

We hold our products to the highest standards with inspections, shipment audits, and failure analyses. Our magnetics solutions comply with all relevant industry standards.

On average, the prices for zatka machine flyback transformers are typically within ₹75 while step-up transformers cost ₹200.

We have served a range of industries and clients in Gujarat, Rajasthan and other parts of India with innovative and cost-effective magnetics solutions for over 35 years. From our manufacturing facilities in Noida, we deliver industry-leading custom and standard magnetic products.

Our professional logistics capabilities and a comprehensive global network of suppliers allow us to offer the shortest lead times in the industry on more than 1,000 magnetics products.

Contact us or request a quote today for your requirements of jhatka machine transformers to see how Shreejee Electronics can help your project.