Transformers and inductors seem very similar in a visual and construction sense. However, they have different applications and unique design and construction elements. Below is a summary about them both, which provides a little guidance on the differences.

Inductors

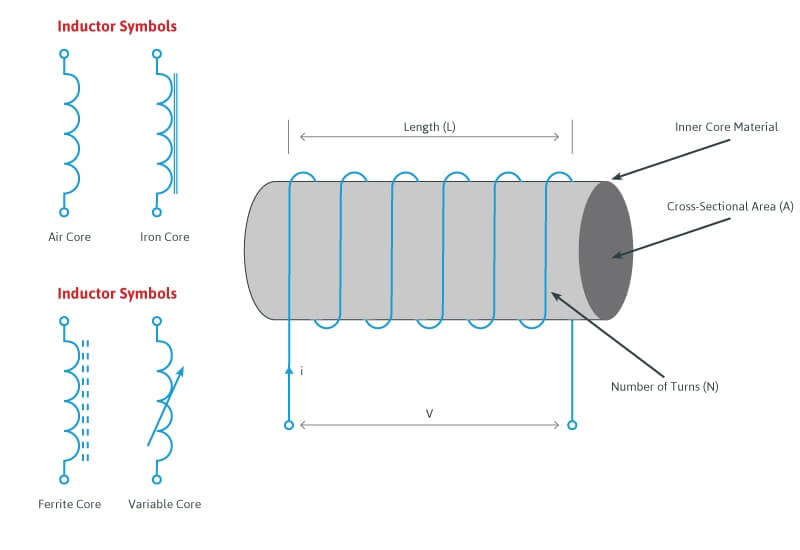

An inductor (a choke or reactor) is a passive two-terminal electrical component. It is made of an electrical conductor; a wire usually wound into a coil. A current flowing through it will store energy temporarily in a magnetic field in the coil. If the current flowing through changes, this creates a voltage (Faraday’s Law).

An inductor is characterized by its inductance, the ratio of the voltage to the rate of current change, which has units of Henry (H). Inductors have values that range from 1 µH (10−6H) to 1 H. Most inductors are made of a magnetic core made of iron or ferrite, which increases the magnetic field and, therefore, the inductance. Inductors are widely used in alternating current (AC) electronic equipment. They are used to block AC while allowing DC to pass (chokes). Electronic filters need chokes to separate signals of different frequencies, and when combined with capacitors, they make tuned circuits.

At Shreejee Electronics, we manufacture many different inductors, from automated to handcrafted methods. There are toroidal winding machines, machines capable of winding copper strips and facilities to wind air coils.

We use a wide variety of core materials, such as iron, ferrite, iron powder, amorphous and a wide variety of conductors, such as enameled wire, copper strip and high voltage insulation wire.

The inductors we produce are used in Switch Mode Power Supplies (SMPS), used for Electromagnetic Compatibility (EMC) control, as security sensors and in audio loudspeakers (see industrial applications).

Transformers

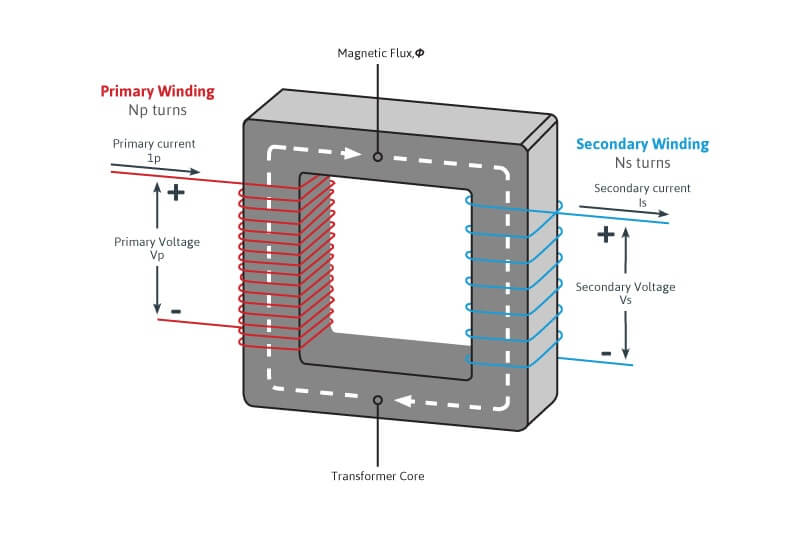

Essentially, a simple transformer consists of two coils of insulated wire. In most transformers, the wires are wound around an iron-containing structure called the core. One coil (the primary) is connected to an input source of alternating current that produces a constantly varying magnetic field around the coil. This magnetic field, in turn, creates an alternating current in the other coil. This secondary coil is connected to a separate electrical circuit to give an output.

The ratio of the number of turns in the primary coil to the number of turns in the secondary coil (the turns ratio) determines the ratio of the voltages in the two coils. For example, if there is one turn in the primary and ten turns in the secondary coil, the voltage in the secondary coil will be ten times that in the primary. This type of transformer construction is called a step-up transformer.

If there are ten turns in the primary coil and one turn in the secondary, the voltage in the secondary will be one-tenth that in the primary. This kind of transformer is called a step-down transformer. The ratio of the electric current strength, or amperage, in the two coils is inverse to the voltage ratio; thus, the electrical power (voltage multiplied by amperage) is the same in both coils.

In an autotransformer, there is only one coil with both circuits connected to it. One circuit contains a larger segment of the coil (which has more turns) than the other. Please find out more about autotransformers in our detailed blog post.

At Shreejee Electronics, we manufacture a variety of transformers, including ferrite, toroidal and laminated. These are produced using multi-head automated machines (see video), semi-auto machines, copper strip winding machines, hand winding machines and various toroidal coil winding techniques and machines.

Various core and conductor materials are used to specifically suit the transformer’s power, frequency, and insulation requirements. Core materials include iron, ferrite, iron powder, and amorphous. They are in the full range of shape styles, such as E core variations, laminations, RM cores, etc. Conductor material is usually copper but can be enameled wire, copper strip, high voltage insulation wire and litz multi-stranded wire.

Transformers we have produced are used in many applications, such as SMPS for LED lighting, mains power conversion for commercial and medical uses and high voltage (HV) transformers for applications such as electrostatic spraying.

We offer a bespoke service to our clients, working to their design requirements. All of the products which we produce are unique to the individual project. So if you have a project you wish to discuss with us, please raise a Request for Quote.