An electric power transformer features primary, secondary, and sometimes tertiary windings. The flux linkage between these windings drives the transformer. For effective flux linkage, one low reluctance magnetic path is provided in the transformer. This path is known it typically in the core.

Generally, the core is made from different materials like silicon steel, ferrites, et cetra. In this post, we will discuss one of the essential types of cores – ferrite cores. What are they? What are their benefits? Do you have more questions?

What are Ferrites?

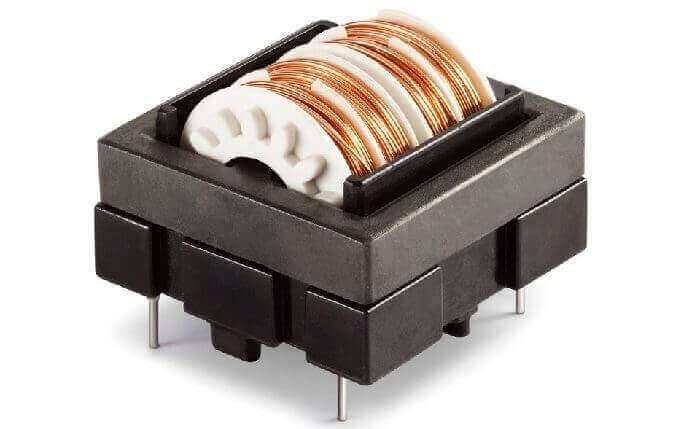

Ferrites are non-conductive ceramic compounds that are ferromagnetic in nature. When the windings of transformers are made from ferrites, they are called ferrite type transformers. Ferrite cores in transformers are made from iron oxides and are combined with zinc, nickel, and manganese compounds. These compounds have very low coercivity and are known as soft ferrites.

Ferrites have several advantages over the other magnetic core transformers due to their mechanical and electrical properties. These include high current resistivity, low eddy current losses over a vast frequency range, and high permeability. These properties make ferrite transformers ideal for various high-frequency transformers, adjustable inductors, wideband transformers, and high-frequency circuits from 10 kHz to 50 MHz.

Today, ferrite cores are available in a variety of material and geometrical combinations.

What are the Different Types of Ferrite Core Type Transformers?

The ferrite cores are distinguished into two types:

- Manganese Zinc Ferrite (MnZn): The chemical formula is (MnaZn(1-a)Fe2O4). These cores have higher saturation levels, as well as higher permeability than NiZn. MnZn cores are ideal for applications with an operating frequency of less than 5MHz. The impedance of these cores makes them suitable for inductors up to 70 MHz.

- Nickel Zinc Ferrite (NiZn): The chemical formula is NiaZn(1-a)Fe2O4. These cores have higher resistivity than MnZn and are used in applications where frequencies range from 2MHz to several hundred MHz. NiZn is considered ideal for inductors above 70 MHz. These cores are temperature sensitive and have a low Curie temperature (under 500oC).

The ferrite materials lose their magnetic properties at a specific Curie temperature. Hence, this fact should be considered while selecting ferrite cores for your transformer.

Are Ferrite Cores Available in Different Shapes?

Yes, they are available. Ferrite cores are classified by shapes such as:

- E, I Cores: These cores feature simple winding of bobbin and have easy assembly. E, I cores are used in power, differential, telecom inductors, broadband, converter, and inverter transformers.

- ETD Cores: These cores feature a center post with a minimum winding resistance. Engineers can optimize the dimensions of these ETD cores for power transformer efficiencies. These cores are ideal for power transformers, as well as inductors.

- EFD Cores: The EFD cores feature cross-sectional areas, which make them ideal for compact transformers and various inductor and transformer applications.

- EER Cores: The cores feature a round center post, which allows a shorter winding path length than a square center post.

Here’s a shot video, on how ferrite cores are constructed.

Are there any selection guide for choosing the right ferrite core?

Here are some free software that can help you design your next transformer application based on ferrite cores.

If you wish to source your ferrite core transformers from a reliable source, you can always consider Shreejee Electronics. The company provides ferrite cores in various specifications to meet your application requirements.